Track, Trace & Authenticate

Industrial Components

How Countermark gives customers the security that they are receiving genuine components

Make sure customers are getting your authentic, safe components. Counterfeit products are unlikely to have met the stringent checks that a genuine product goes through and are often sub-standard or worse, dangerous.

Countermark is an easy solution designed to reduce the risks of using fake components. It can be used to control your supply chain and help customers trace their item back to you, giving them the confidence that they have received a genuine component.

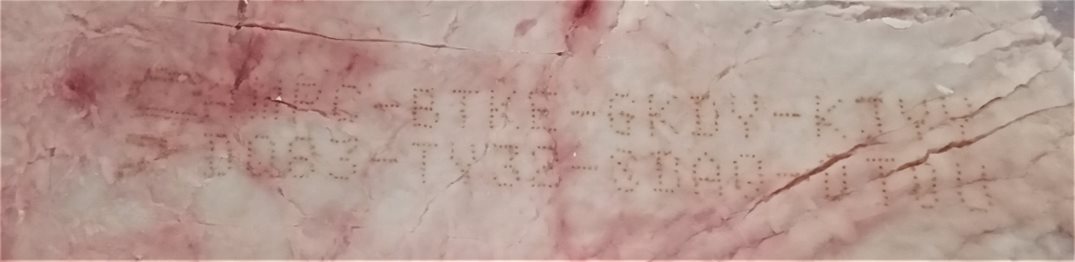

Countermark can act as a digital signature, uniquely identifying each individual product that you ship. Countermarks can be applied with Laser Markers or with Continuous Ink Jet Printers (the same type of printers widely used for “best before” data). In the event of a product failure, the unique Countermark can be used to demonstrate the origin (real or counterfeit) of a suspect part.

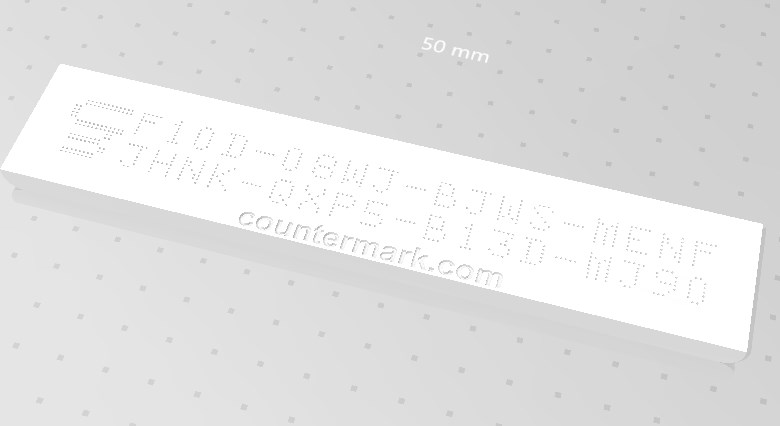

Traceability of additive manufactured parts

3D printing or additive manufacturing is already bringing massive changes to assembly lines, allowing economic low production volumes and personalisation of designs. Countermark allows secure traceability of these unique parts.

3D printing is great for the "does it fit together" prototypes, now companies want to put additive manufactured parts into aircraft, boats, trains, cars, medical and food applications.

Serialisation based on barcodes and 2D codes needs high black and white contrast ratios that you cannot get when everything is the same colour.

The algorithms used in Countermark can read low contrast printed data with a fallback of human-readable characters; this means that unique machine-readable data can now be added to 3D parts by simply merging the Countermark into the source CAD data.

The Countermark links to the source data used, the machine, the resin, the works order or simply the name of the designer.

There is an API for organisations who want to automate the process.

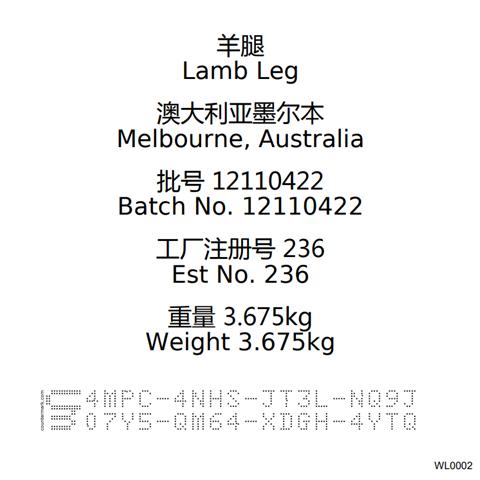

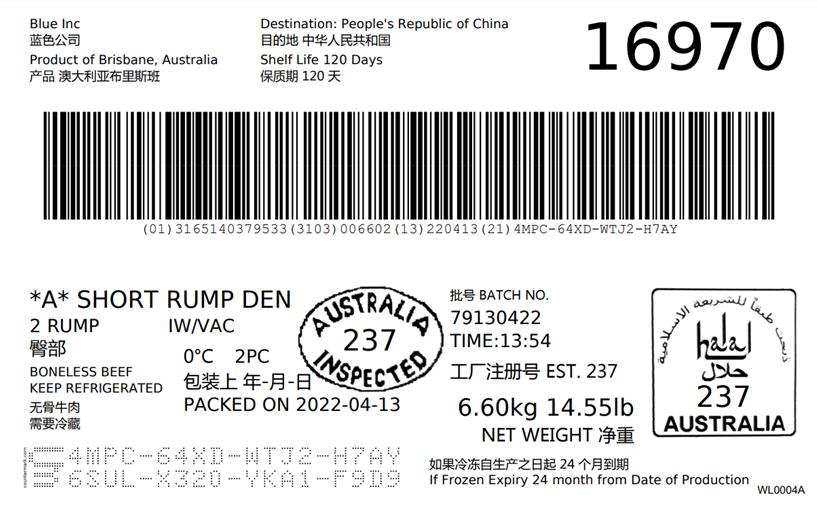

Food Safety

Food Safety - Case study for the Australian Meat Processor Corporation (AMPC)

AMPC wanted to know how customers of the Australian Red Meat industry could be certain of the origin of their food, (beef, lamb, goat). Australian red meat is great food and commands premium prices when sold in export markets. These premium prices increase the risk that some retailers in some export markets might substitute Australian product for lower grade food from the local market.

We have carried out two linked case studies to show that Countermark could provide the data structure to prevent food fraud. This was demonstrated with edible ink Countermarks directly printed onto the meat and with digitally signed labels applied to packaging. Every label in the food supply chain, from abattoir to consumer was created as a secure document and signed with a Countermark.

The Countermark App allowed anybody to securely verify their purchase and it gave full visibility of the food supply chain to the farmers. Customers could see where their food was raised and even enjoy recipes posted on the farmers’ websites.

Countermark can provide enhanced market visibility and provide full farm to plate and plate to farm traceability.

Conventional secure documents need a range of metals, plastics and chemicals that would not be allowed in food packaging. Countermark allowed us to convert all food labels to secure documents using existing food approved printers, label stock and ink.

By making all of the meat labels secure documents that would be impossible to falsify, we really showed the flexibility of Countermark and the skills of the Countermark team.

Countermark can give proof of abattoir, farm and meat grade.

Appliance Spares

Reduce the risk of Counterfeits and engage with your customers

Help fitters to avoid fake spares. Unfortunately, there is a huge market for counterfeit spare parts. Using Countermark technology, you can give fitters the security of knowing that they have obtained certified genuine parts, helping protect your reputation and revenue from fake spares.

Countermark can also be used as a customer engagement tool. The fitter scanning the Countermark as part of their repair can extend repaired product warranty and help identify the end customer with the repaired item.

Use the information about the end user to engage and give them a great service, working in a similar way to a product warranty. Knowing when a part has been fitted allows you to approach the end user at the right time for a replacement product or for maintenance.

Using Countermark technology to ensure a document or product is genuine, you can help to avoid the very real risks associated with counterfeit products or unskilled staff.

Easily created from your desk, a Countermark can be attached to physical or digital items, even remaining readable when damaged. Ultimately, it is a unique digital fingerprint that can be traced back to your organisation, giving security that a genuine component has been supplied.

Contact our knowledgeable team today to learn more about Countermark technology and how it can benefit your organisation.

Automotive Parts

Appliance Spares